Anacardium Occidentale by-Product: A Review on Sustainable Application and Added-Value

A B S T R A C T

Cashew (Anacardium occidentale) tree is mainly known for the production of cashew nuts. Cashew apple also known as pseudo-fruit is the by-product of cashew nut production. The fruit is often neglected due to its high perishability. It is important to note that cashew nut production leads to average wastage of around 2 million tons in Maharashtra alone. Additionally, cashew apple needs to be known for its value-added potential as it is a rich source of ascorbic acid, polyphenols, minerals, vitamins and sugars. Recovery of these high-value nutrients may render the cashew apple processing sustainable and will further add value to the fruit waste. The authors herein review the sustainable application and benefit of cashew apple as a by-product of cashew nut production.

Keywords

Cashew apple, preprocessing, value addition, sustainability

Introduction

Cashew (Anacardium occidentale) is an evergreen tropical tree with its origin in north-east Brazil [1]. It was introduced in India by the Portuguese around 1590, mainly for its ability to control erosion observed along the coastal region [2]. The Cashew tree is a cash crop planted for cashew nut production. The cashew nuts are rich in carbohydrates, fats and vitamins A, D, E and K. It is also a source of minerals like calcium, magnesium, potassium, sodium, iron. The cashew kernels are consumed as snacks after roasting and are even processed for the production of different value-added products Currently the major players in the world for cashew nut production are India, Vietnam, Ivory Coast, Tanzania, Brazil and Mozambique [3, 4].

Cashew Apple

It is important to note the cashew fruit has two parts nut and cashew apple. The color of the apple turns into red, yellow or orange when ripe and the weight varies from 15-20 g or up to 200 g [5, 6]. The cashew apple is much larger than the nut, normally with a ratio of 1:8 and 1:10 [7]. Therefore, for every ton of cashew nut, approximately 5-10 tons of cashew apples are produced [8]. Unfortunately, the cashew apple is discarded during cashew nut production thereby generating a huge amount of waste. However, studies have shown that cashew apple is a rich source of carbohydrates, minerals, vitamins, amino acids, carotenoids, phenolics, organic acids, and antioxidants [5, 8-12].

The major reason for fruit wastage is its astringent flavor and highly perishable nature. Generally, the ripe cashew apples are juicy, fibrous with very delicate skin and are eaten as such or sprinkled with salt and sugar. The high levels of reducing sugar (55 to 65 %, dry basis) in the fruit can be accounted for its perishable nature as it causes rapid spoilage due to microbial activity [13]. It is important to highlight that there is an immense need to utilize this rich and nutritious fruit and also prevent the associated economic loss. The authors herein, present a comprehensive review of the utilization of cashew apple and its applications in various industries.

Challenges in Cashew Apple Processing

The seasonal production of cashew apple is one of the major challenges in a cashew apple processing along with its astringent and acrid principles. The complete spoilage of cashew apple can occur within an hour after harvest and this perishable nature leads to the problem of storage. Moreover, its utility is limited because of high susceptibility to injury, which leads to microbial spoilage during harvest. More than 63% of cashew apple collected at the ripe stage exhibit moderate to heavy damage [14].

A study by Quiroz C et al. was conducted to evaluate the effect of damage and storage conditions on the amount of vitamin C, total polyphenols, proanthocyanidins and antioxidant potential of cashew apple at 20°C, 27°C and 40°C [15]. It was observed that there was a decrease (12 to 38%) in ascorbic acid at these three temperatures. After 24 hours the fruits kept at 20°C and 27°C showed an increased level of phenol content, but the higher temperature than room temperature showed the decreased in level. Proanthocyanidins were most affected at 40°C than the other two temperatures. Bioactive compounds were also significantly affected because of cutting and storage conditions. The results showed a significant impact of temperatures and damage on fruit quality. The cashew apple possesses great potential for developing the value-added products due to its functional activity which needs to be explored.

Value Added Products

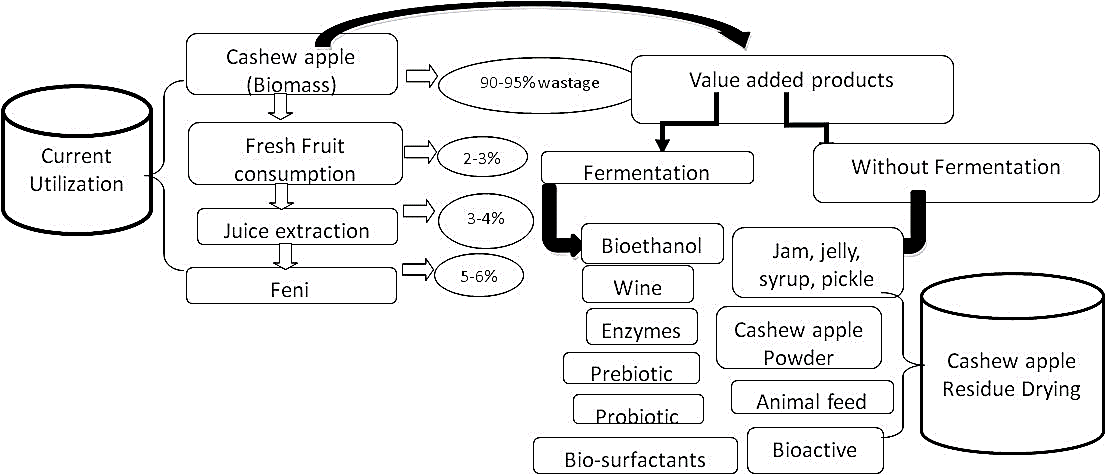

The cashew apple can be successfully converted into value-added products in two ways; with fermentation and without fermentation, as shown in (Figure 1). In India, cashew feni is the only commercially produced value-added product in Goa. Feni is produced by the method of fermentation.

Figure 1: Cashew apple Bio refinery System.

Feni

This is the only by-product produced in India from cashew apple. Four grades of cashew liquor have been discovered, but only the Feni is produced in Goa state due to government restrictions on a commercial scale. In the traditional method of making cashew Feni, the only tree ripened cashew apples that have fallen down are picked and taken for crush. The cashew apples are de-seeded and then dropped into the stomping area. The area is called colmbi and it is like a rock cut into a basin shape. The cashew apples are stomped to release the juice. Nowadays people are using cages for juice. The juice is then collected in a huge earthen pot called as Kodem; the pot is buried under the ground. The juice is then distilled in earthen or copper pots. In the traditional distillation, the cashew juice is put into the big pot called Bhann. The Bhann served as a closed boiler. It is connected to a smaller pot called Launni by means of a conduit. The Launni serves as a receiver or collector.

The juice in the big pot then boiled by burning firewood under it. The first stage of processing generally done on big fire, but the later stage of distillation has to be done on slow fire to keep the pressure and heat under control. This complete process of distilling Feni takes about 8 hours and locally called as Bhatti. The liquor produced from cashew is of three grades called, Urrac, Cazulo and Feni. The Urrac is the product of the first distillation. It contains about 15% of alcohol. The second product is Cazulo it is moderately strong. It contains 40% alcohol. The product after third distillation is called Feni. The Feni contains 45% of alcohol. It has a long shelf life [16]. There are around 4000 such mini traditional distilleries are there in Goa. It is known that there are 7,000 shops, bars and taverns’ in Goa selling Feni and other liquors, either wholesale or retail. About 55% of them are in north Goa and 45% in South Goa [17, 18].

Wine

Wine refers to a product from any of the fruit by a process of fermentation. Like other fruits, good quality wine can be produced from cashew apple. Many studies have been conducted to prepare wine from cashew apple and were evaluated for its sensory parameters [19]. The appearance of cashew apple wine was slightly yellowish, acidic in taste, high in tannin and low in alcohol concentration.

Mohanty S et al. conducted a study to prepare and compare a cashew apple wine with a commercial grape wine in terms of sensory and quality attributes [20]. The results showed that the cashew apple wine is acceptable to the consumer, but it showed some inferior scores compared to grape wine in terms of taste, aroma, and flavor. The main reason could be the high tannin content in cashew apple wine. The cost of production was low as compared to other fruit crops as cashew apples are easily available. Thus, the conversion of cashew apple into wine is a good alternative to produce a commercially viable product in future. This may contribute to resolve the problems of fruit wastage and spoilage and generate extra revenue for the cultivators. It is essential to highlight the variety of value-added products without fermentation which can be a healthy and economical option to the consumers. The value-added products derived from cashew apple by a non-fermented method are enlisted in (Table 1) along with brief detail of their preparation.

Table 1: Value Added Products of Cashew Apple.

|

Sr. |

Cashew appleproducts |

Methods |

|

1 |

Syrup [21] |

Sugar (2kg/lit) added to clarified juice and 15 g/l citric acid is added. |

|

2 |

Ready to serve beverage (RTS)[14] |

1 lit of RTS drink; 120 g of sugar per to 730 ml of water and boiled. 150 ml of clarified cashew apple juice is added. |

|

3 |

Squash [22] |

1 lit of squash, 400 g sugar and 2.5 g of citric acid were added to 350 ml of water and boiled. Then 250 ml of clarified cashew apple juice is added. The squash is stained, bottled and sealed. |

|

4 |

Jam [14] |

1 kg of cashew apple pulp, 1 kg sugar and 2-5 g of citric acid were added. The pulp is cooked until the jam is prepared. The jam is poured into jars and sealed. |

|

5 |

Soda [14] |

Cashew soda is prepared by mixing of 10 ml chilled carbonated water at 100 psi pressure. 50 ml syrup was added to give 200 ml cashew soda. |

|

7 |

Vinegar [14] |

Vinegar is prepared by adding 158 g sugar, 1 lit of juice and 2g of yeast. It was recommended to have 12 days of alcoholic fermentation, then mother vinegar was added, and the mixture was kept for 2 weeks. Acidity level is 4-5 %. |

|

8 |

Cashew apple candy [14] |

The cane sugar was used for the preparation of the same. The draining and drying was used. .1 kg of cashew apple is placed in 1 kg of sugar syrup for 2-3 weeks. The sugar is added in phased manner. After 2-3 weeks, the apples were removed and dried to obtained candy. |

|

9 |

Confectionaries [23] |

Cashew apple chocolate, biscuit etc was made using Powdered cashew apple and pulp along with addition of ghee and milk powder. |

|

10 |

Pickle [14] |

Green apple pieces were used for pickle by adding chili powder, turmeric powder, asafotedia powder, mustard powder, fenugreek powder, ginger, garlic, green chilli vinegar, gingelly oil and salt. |

|

11 |

Chutney [23] |

This was made by adding ingredients in the cashew apple slices like onion, ginger, cumin, pepper, cardamom, cinnamon, coriander, vinegar, salt and sugar to cashew apple slices. |

Jam, Jelly, Candy, Syrup

Cashew apple can be utilized for the production of homemade products like jam, jelly, syrup, nectar, juice etc. Cashew beverages are commercialized in some countries like Brazil and India [24]. Other products are at the cottage level stage. Sensory evaluation of these products shows good consumer acceptance. Clarified juice, juice concentrate, syrup, squash and RTS drink are some of the nutritious and refreshing beverages that can be made from the unfermented juice of cashew apples by adding varying concentrations of sugar, citric acid and preservatives [14]. In India, the Kerala Agricultural University has developed and standardized the techniques for value-added products like syrup, candy, juice etc. Cashew apple syrup, soft drinks and cashew apple candy are the commercial products sold in India as well as abroad.

Cashew Apple Powder

Cashew apple can be successfully converted into cashew apple powder. The nature of Apple is very perishable it cannot be stored even for a day at room temperature. The powder can be used in different preparations like convenience food. A study was conducted to prepare powder from cashew apple without juice and by drying cashew apple residue. This dehydrated powder was used successfully in the preparation of wheat laddu (Indian sweet), sponge cake, chocolate, and soup recipes at the rate of 10% substitutions [25]. Similarly, another study was conducted by blending cashew apple juice and skimmed milk and dehydrated by the process of spray drying. In this case, obtained powder was used in the preparation of halwa and lassi (Indian traditional sweets). The products were tested against appearance, texture, aroma, taste and overall acceptability. It was observed that the physical appearance of the product was not much appreciated by the consumer, but the mean score showed that products were accepted for consumption. It was interesting to note that, vitamin C content of dry powder is considerably higher as compared to other fresh fruits.

Animal Feed

Many reports have suggested the use of cashew apple as an animal feed. Cashew apple residue can be easily converted into animal feed and can be used for animals like cattle, sheep and goats. The cashew apple is a promising source of feed for dairy cows in Vietnam and Brazil. Cashew peel is a good feed for poultry because of its nutritional content (7.6% protein, 12.3% fat and 59.2% carbohydrate). The dry matter content in cashew apple residue is about 17 to 23% depending upon the extraction method. The main features about nutritive value of cashew apple residues are crude protein 9-12%, nitrogen-free extract comprising of 70-75% of dry matter, including soluble carbohydrates 23-29%, crude fat 5.6 to 6.5%, and crude fiber 8.3-9.8%. These values are nearly similar to most popular animal feeds like corn, broken rice, rice bran etc. The nutritive digestibility ratio is, however, moderately low because of lignin, cellulose and tannin content of cashew apple residue [14].

Bioethanol

The principle fuel used as a petroleum substrate is bioethanol. There is a huge potential to use cashew apple for the production of bioethanol. It is estimated that cashew apple can yield 8 to 10% of ethanol. Every kilogram of nut provides a sufficient quantity of cashew apples to produce 500-600 ml of ethanol of about 70% purity.[14] A study that was conducted to evaluate the optimum conditions of different parameters while producing ethanol from cashew apple used the immobilized yeast cell technology to produce bio-ethanol from cashew apple juice. The result showed the maximum extraction of bioethanol up to 7.62% with a pH of 6.0, temperature 32.5°C and inoculums level of 8 per cent for 24 hours [21, 26].

Probiotic Products

Probiotics are live microorganisms which, when administered in adequate amounts, confer a health benefit to the host. These probiotics must be alive when they are administered [27]. Current probiotic beverages mainly contributed to the dairy sector. It is important to explore more plant-based products which can be used for probiotic products. The main concerns for searching different options are an allergy to the dairy products, dietary preferences or some health issues. Cashew juice is a plant-based alternative to probiotics. It has various health effects like recovery from gastrointestinal infections, antimicrobial activity, reduction in lactose intolerance, decreased of serum cholesterol levels, immunity stimulation, ant mutagenic properties, anti-carcinogenic ability, anti-diarrheal activities, and favorable effects in inflammatory bowel diseases [28].

Prebiotics

Prebiotics are generally defined as non-digestible polysaccharides and oligosaccharides, which promote the growth of beneficial lactic acid bacteria in the colon and exert antagonism to salmonella sp. or Escherichia coli, limiting their proliferation [19]. Rabelo MC et al. evaluated enzyme-based biosynthesis of prebiotic oligosaccharides with the use of cashew apple juice acting as a substrate by Leuconostoc citreum B-742 [29]. About 80% oligosaccharide yield was observed when sucrose levels were lower than 60 g/l and reducing concentrations were higher than 100 g/l. Honorato LT and Rodrigues conducted a study on dextransucrase stability in cashew apple juice [5]. In this study, the production of dextransucrase using cashew apple juice as a substrate was examined. The stability of the crude enzyme was noted at 30°C for 30 h and at 4.5 to 5.5 pH. The partially purified enzyme so obtained was also stable in non-fermented cashew apple juice maintained at pH 5.0 for the duration of 96 hrs and at 30°C.

Da Silva IM et al., investigated the prebiotics property of cashew apple juice [30]. It was found that cashew apple juice worked as a source of enzyme acceptor being rich in glucose and fructose. The biosynthesis of dextransucrase enzyme was carried out using fermentation by the bacterium Leuconostoc mesenteroides NRRL B512F wherein a culture medium contained sucrose as the only source of carbon. The highest yield of oligosaccharides was 104.73 g/L. The qualitative analysis indicated 25 g/L and 75 g/L of sucrose and reducing sugar concentrations, respectively. It was thus possible to obtain a good amount of oligosaccharides having a degree of polymerization up to 12.

Bioactives and Antioxidant Potential of Cashew Apple

Bioactives can be defined as secondary plant metabolites which bring forth pharmacological and/or toxicological effects in the human body [31]. The beneficial effects may be due to the action of antioxidant potential of bioactive compounds [32]. The antioxidant potential can be defined as the capacity to scavenge (capture) reactive oxygen radicals (ROS) and electrophiles thereby reducing oxidative damage in the blood.

The accumulation of these species may have serious consequences including cancer. However, only a few randomized clinical trials are conducted to test the antioxidant potential of these bioactive compounds and the results are found to be controversial. The reason for the varied final outcome of the trials may be inbound factors that have an impact on the stability of the bioactive compounds in different pharmacological forms and in gastrointestinal tract [33].

On the other hand, in vitro assays or animal studies highlight the beneficial effect of high fruit and vegetable diets in lowering the risk of chronic health disorders not only because of their high fiber and low fat content but also for the anti-oxidant potential of the bioactives like ascorbic acid or polyphenol [34]. Therefore, public health policies promote consumption of fruits and vegetables as a good source of naturally present antioxidants. Natural antioxidants include flavonoids, isoflavones, phenolic acids, carotenoids, tocols etc. Apart from their beneficial antioxidant potential, these naturally found bioactives are helpful for food preservation. They may be used as components of composite food formulations or can be extracted and subsequently added to foods. Da Silva LMR et al. conducted a study to quantify bioactives in pulps and by-products of various tropical fruits from Brazil including cashew apple [35]. The total phenolics in cashew apple were 5861 gallic acid equivalent (GAE/100g). Thus, cashew apple seems to be a good store of bioactive molecules which might be helpful for treatment in diseases like fever, sore throat, and up to cancer.

Another study conducted by Lopes et al. in Brazil that monitored the antioxidant potential of cashew apples at different maturity stages while ripening [36]. The clones were analyzed for Vitamin C, total carotenoid, total anthocyanin, yellow flavonoid, polyphenol content and total antioxidant capacity. The results showed a gradual increase in vitamin C and the highest value was obtained for ripe cashew apple (279.37 mg/100gm). The total carotenoid content increased with ripening, which displayed a considerable level of antioxidant activity.

Health Benefits of Cashew Apple

Cashew extract contains anarcardic acid, an important antioxidant used to eradicate the cancer cells and even limit the pigmentation effects of aging [35, 36]. Therefore, the extract can be effectively utilized in cosmetic industry especially in the preparation of anti-aging creams and shampoos. The cashew apple is also known to have anti-bacterial properties that are effective in treating stomach ulcers and gastritis. It is used safely to treat infant's thrush or oral infections and is also a known remedy for scurvy effect [37, 38].

Traditionally cashew apple is used for several ailments. It is used as a tonic for mothers during birthing and post-partum care. It possesses antiscorbutic properties and is thereby useful in kidney disorders and advanced cases of cholera. Juice of Cashew apple can be preserved for a period of 2 to 3 years by exposing it to the sunlight for 15 days. This juice is said to be effective as a remedy for diarrhea and fever for humans and animals (information obtained through an interview). Additionally, a study reported enhanced fat utilization during high-intensity exercise in men who drank cashew apple juice [11]. However, the information about the level of consumption of cashew apple for beneficial effect is not available. The clinical trials with humans need to be explored to see the effect of these therapeutic and nutraceutical potential.

Economic Gains

The Kerala agricultural university has proposed a value addition of cashew apple into some traditional products like pickle, candy, pulp, juice etc. They have developed self-help groups to manufacture these products. The net profit of these kind of manufacturing units is Rs. 8500 per individual per month for the domestic market [39]. In Maharashtra, the current price of 1 kg of cashew nut is approximately Rs. 150 per kg. The same quantity of nut can produce 10 kg of cashew apple. The cashew apple can add extra income of Rs. 50 for the same quantity considering Rs. 5 per kg of cashew apple (information through farmers and processors). The added income will give sustainability to cashew farmers. The cashew apple if processed efficiently can generate more revenue through various value-added products. Currently, world production of cashew apple is approximately 30 million tons per annum out of which 95% is wasted in percent and approximately Rs. 4 billion [40]. The scientific study for the sustainability of these product, markets and export potential needs to be explored to strengthen the industry.

Conclusion

The opportunities to broaden the use of cashew apple are immense. The major hindrance in utilizing the cashew apple and related products to their full potential is current lack of storage and processing level technology. In order to overcome this difficulty and provide greater sustainability to cashew nut processing industry it’s important to execute few steps starting with creating awareness among cashew nut cultivating farmers and consumers about the nutritional values and health benefits of the cashew apple. The key areas for development of cashew apple processing such as technology and techno-economic feasibility, quality check and quantification of the products etc needs to be identified.

There is also a need to perceive the wide scope for cashew apple products in the coming era. Hence, research and development are pre-requisite in the areas of developing easy and low-cost technology for storage and preservation of cashew apple. Further to make the cashew apple product available for everyone, the food and pharmaceutical industry should join hands and help in scaling up the cashew processing industry. It is equally essential to have innovative product development research and vigilant market analysis to make sustainability of cashew industry a success.

Acknowledgement

Authors thank Ms. Poonam Pawar for additional editorial support.

Conflicts of Interest

None.

Article Info

Article Type

Review ArticlePublication history

Received: Mon 30, Mar 2020Accepted: Thu 30, Apr 2020

Published: Thu 28, May 2020

Copyright

© 2023 Ketaki Barve. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Hosting by Science Repository.DOI: 10.31487/j.JFNM.2020.01.04

Author Info

Agte Vaishali Arora Amit Ketaki Barve

Corresponding Author

Ketaki BarveCTARA, IIT Bombay, Mumbai, Maharashtra India

Figures & Tables

Table 1: Value Added Products of Cashew Apple.

|

Sr. |

Cashew appleproducts |

Methods |

|

1 |

Syrup [21] |

Sugar (2kg/lit) added to clarified juice and 15 g/l citric acid is added. |

|

2 |

Ready to serve beverage (RTS)[14] |

1 lit of RTS drink; 120 g of sugar per to 730 ml of water and boiled. 150 ml of clarified cashew apple juice is added. |

|

3 |

Squash [22] |

1 lit of squash, 400 g sugar and 2.5 g of citric acid were added to 350 ml of water and boiled. Then 250 ml of clarified cashew apple juice is added. The squash is stained, bottled and sealed. |

|

4 |

Jam [14] |

1 kg of cashew apple pulp, 1 kg sugar and 2-5 g of citric acid were added. The pulp is cooked until the jam is prepared. The jam is poured into jars and sealed. |

|

5 |

Soda [14] |

Cashew soda is prepared by mixing of 10 ml chilled carbonated water at 100 psi pressure. 50 ml syrup was added to give 200 ml cashew soda. |

|

7 |

Vinegar [14] |

Vinegar is prepared by adding 158 g sugar, 1 lit of juice and 2g of yeast. It was recommended to have 12 days of alcoholic fermentation, then mother vinegar was added, and the mixture was kept for 2 weeks. Acidity level is 4-5 %. |

|

8 |

Cashew apple candy [14] |

The cane sugar was used for the preparation of the same. The draining and drying was used. .1 kg of cashew apple is placed in 1 kg of sugar syrup for 2-3 weeks. The sugar is added in phased manner. After 2-3 weeks, the apples were removed and dried to obtained candy. |

|

9 |

Confectionaries [23] |

Cashew apple chocolate, biscuit etc was made using Powdered cashew apple and pulp along with addition of ghee and milk powder. |

|

10 |

Pickle [14] |

Green apple pieces were used for pickle by adding chili powder, turmeric powder, asafotedia powder, mustard powder, fenugreek powder, ginger, garlic, green chilli vinegar, gingelly oil and salt. |

|

11 |

Chutney [23] |

This was made by adding ingredients in the cashew apple slices like onion, ginger, cumin, pepper, cardamom, cinnamon, coriander, vinegar, salt and sugar to cashew apple slices. |

References

- Moran EF (1994) Tropical Forests and their Crops. By Nigel JH Smith, JT Williams, Donald L. Plucknett, and Jennifer P. Talbot. Ithaca, New York: Cornell University Press, 1992. xvi+ 568 pp. Illustrations, notes, references, index. Paper $27.95. Duke University.

- Woodroof JG (1995) Tree nuts; production, processing, products 1967.

- Nayar KG Cashew: a crop with unlimited potential. Cashew Bulletin 3: 1-6.

- Das I, Arora A (2017) Post-harvest processing technology for cashew apple–A review. J Food Eng 194: 87-98.

- Honorato TL, Rodrigues S (2010) Dextransucrase stability in cashew apple juice. Food Bioprocess Tech 3: 105.

- Andrighetti L (1994) The world cashew economy. L’inchiostroblu: Nomisma Economic Research Centre, Italy.

- Rocha MVP, Oliveira AHS, Souza MCM, Gonçalves LRB (2006) Natural cashew apple juice as fermentation medium for biosurfactant production by Acinetobacter calcoaceticus. World J Microbiol Biotechnol 22: 1295-1299.

- Akinwale TO, Olubamiwa O, Ajav EA (2001) Cottage processing of cashew apple juice in Nigeria: physico-chemical and sensory evaluation of product. J Food Technol Africa 6: 56-58.

- Spore CTA (2006) Information for agricultural development in ACP Countries.

- De Carvalho JM, Maia GA, De Figueiredo RW, De Brito ES, Rodrigues S (2007) Storage stability of a stimulant coconut water‐cashew apple juice beverage. J Food Process Preserv 31: 178-189.

- Prasertsri P, Roengrit T, Kanpetta Y, Tong Un T, Muchimapura S et al. (2013) Cashew apple juice supplementation enhanced fat utilization during high-intensity exercise in trained and untrained men. J Int Soc Sports Nutr 10: 13. [Crossref]

- Talasila U, Vechalapu RR, Shaik KB (2012) Clarification, preservation, and shelf life evaluation of cashew apple juice. Food Sci Biotechnol 21: 709-714.

- Sivagurunathan P, Sivasankari S, Muthukkaruppan SM (2010) Characterisation of cashew apple (Anacardium occidentale L.) fruits collected from Ariyalur District. J Biosci Res 1: 101-107.

- Mathew J, Sobhana A, Mini C (2013) Opportunities for income enhancement from cashew plantations through cashew apple processing. Proceedings of the second international cashew conference, Kmpala Uganda, CABI International, Wallingford, UK 143-149.

- Queiroz C, da Silva AJR, Lopes MLM, Fialho E, Valente Mesquita VL (2011) Polyphenol oxidase activity, phenolic acid composition and browning in cashew apple (Anacardium occidentale, L.) after processing. Food Chemistry 125: 128-132.

- Mandal RC, Dhandar DG, Dhume CV (1979) Cashew apple liquor industry in Goa. Int Cashew Symposium 108: 172-175.

- Rao EVVB, Swamy KRM, Bhat MG (1998) Status of cashew breeding and future priorities. J Plant Crops 26: 103-114.

- Sawkar K, Noronha L, Mascarenhas A, Chauhan OS, Saeed S (1998) Tourism and the environment case studies on Goa, India, and the Maldives.

- Patel S, Goyal A (2012) The current trends and future perspectives of prebiotics research: a review. 3 Biotech 2: 115-125. [Crossref]

- Mohanty S, Ray P, Swain MR, Ray RC (2006) Fermentation of cashew (Anacardium occidentale L.)‘apple’ into wine. J Food Process Preserv 30: 314-322.

- Costa MCO, Maia GA, de Figueiredo RW, de Souza Filho M, Brasil IM (2003) Storage stability of cashew apple juice preserved by hot fill and aseptic processes. Food Sci Technol 23: 106-109.

- Shivaleela HB, Vaidehi MP (1995) Nutrition value of processed products of cashew apples. Phala Samskarana 408-412.

- Neelakandan T, Usharani G (2009) Optimization and production of bioethanol from cashew apple juice using immobilized yeast cells by Saccharomyces cerevisiae. Am Eurasian J Sci Res 4: 85-88.

- Mini C, Mathew J (2008) Recipes for cashew apple products. Director of Extension, Kerala Agricultural University, Mannuthy, Thrissur, Kerala, India 5-6.

- PPJ (2009) White Gold : An Experience of Cashew 1: 1-4.

- Ohler JG (1988) Extraction and Preservation of Cashew Juice Using Sorbic and Benzoic Acids. Cashew communication 71. Departement of Agricultural Research, Koninklijk Institut voor de Troppen, Amsterdam, ISBN 478386150.

- Rabelo MC, Fontes CP, Rodrigues S (2009) Enzyme synthesis of oligosaccharides using cashew apple juice as substrate. Bioresour Technol 100: 5574-5580. [Crossref]

- da Silva IM, Rabelo MC, Rodrigues S (2014) Cashew juice containing prebiotic oligosaccharides. J Food Sci Technol 51: 2078-2084. [Crossref]

- Bernhoft A, Siem H, Bjertness E, Meltzer M, Flaten T et al. (2010) Bioactive compounds in plants–benefits and risks for man and animals. Norwegian Acad Sci Lett 13-14.

- Clifford MN (1995) Understanding the biological effects of dietary complex phenols and tannins and their implications for the consumer’s health and well-being. Eur. Proj, Report of the European project FAIR-CT95-0653. European Community Programme for Research, Technological Development and Demonstration in the field of Agriculture and Fisheries.

- Babbar N, Oberoi HS, Sandhu SK (2015) Therapeutic and nutraceutical potential of bioactive compounds extracted from fruit residues. Crit Rev Food Sci Nutr 55: 319-337. [Crossref]

- W H Organization (2003) Diet, nutrition, and the prevention of chronic diseases. World Health Organ Tech Rep Ser 916. [Crossref]

- Ribeiro da Silva LM, Teixeira de Figueiredo EA, Silva Ricardo NM, Pinto Vieira IG, Wilane de Figueiredo R et al. (2014) Quantification of bioactive compounds in pulps and by-products of tropical fruits from Brazil. Food Chem 143: 398-404. [Crossref]

- de Lopes MM, de Miranda MRA, Moura CFH, Enéas Filho J (2012) Bioactive compounds and total antioxidant capacity of cashew apples (Anacardium occidentale L.) during the ripening of early dwarf cashew clones. Ciência e Agrotecnologia 36: 325-332.

- Kubo I, Ochi M, Vieira PC, Komatsu S (1993) Antitumor agents from the cashew (Anacardium occidentale) apple juice. J Agricultural Food Chem 41: 1012-1015.

- Cavalcante AAM, Rübensam G, Erdtmann B, Brendel M, Henriques JAP (2005) Cashew (Anacardium occidentale) apple juice lowers mutagenicity of aflatoxin B1 in S. typhimurium TA102. Genet Mol Biol 28: 328-333.

- Gyedu Akoto E (2011) Utilization of some cashew by-products. Nutr Food Sci 41: 393-400.

- Malhotra SK, Hubballi VN, Nayak MG (2017) CASHEW: Production, Processing and Utilization of By-products. Processing and Utilization of By-products Directorate of Cashewnut and Cocoa Development, Cochin, Kerala, India.

- Bhat MG, Nagaraja KV, Rupa TR (2010) Cashew research in India. FOCUS 5: 1-16.

- Mini C, Mathew J, Augustin A (2005) Technologies for cashew apple processing. Directorate of Extension, Kerala Agricultural University, Mannuthy, Trissur, India 55.

- Sobhana A, Mathew J, Mini C (2013) Utilization of Cashew Apple in the Food Industry in India. Int Cashew Conference 150.