The Effect of Three Polishing Systems on the Surface Rugosity of One Composite Resin

A B S T R A C T

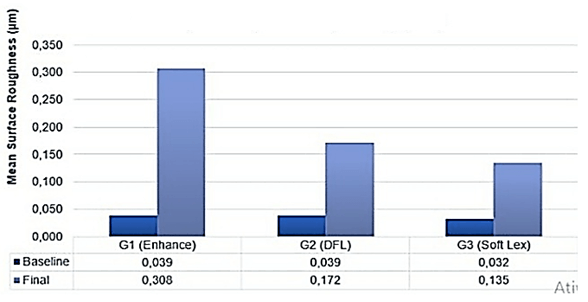

Direct restorations in composite resin require superficial rugosity appropriate to guarantee a surface free of biofilm buildup, which interferes with the durability of the restoration, its properties and the aesthetic aspect. Thus, it is relevant to know the behaviour of the finishing and polishing systems. The in vitro study aimed to compare the polishing efficiency of three different polishing systems in promoting the surface smoothness of a nanocomposite resin. Sixty specimens of the nanocomposite resin Filtek Z350 XT (3M) were made, randomly divided into three groups (n=20), according to the tested polishing systems: Enhance (Dentsply), DFL Polishers, and Sof-Lex Spiral (3M). The surface rugosity of the samples was measured by means of the rugosimeter equipment. The data were analysed through statistical tests: ANOVA two-way and post-hoc Tukey. The results indicated Sof-Lex (3M) polishing discs as the ones with the lowest average surface rugosity (0.13µm), presenting statistically significant results (p<0.05); followed by the abrasive rubbers of the DFL system (0.17 µm) and the Enhance system (Dentsply), which showed greater average surface rugosity (0.30 µm). The lowest surface rugosity of the composite resin evaluated in this study (Z350 XT- 3M) was obtained after polishing with the multi-step system (Sof-Lex), from the same manufacturer.

Keywords

Composite resins, dental polishing, dental materials

Introduction

Composite resin is a material that constantly evolves in terms of physical, mechanical and aesthetic properties, and is widely indicated for aesthetic and functional restorations. However, its long-term clinical success depends greatly on obtaining a glossy and polished surface by means of finishing and polishing procedures, considered essential at the end of the restoration's fabrication [1-3]. Through finishing, the anatomy, occlusal morphology and the tooth-composite interface are refined, but a rougher surface is formed, which should be removed by polishing, thus avoiding biofilm accumulation, gum irritation, recurrent caries and discolouration of restored teeth in the long run [4]. Both procedures play an important role in the aesthetic outcome of direct restorations. Otherwise, an unpolished or poorly polished surface favours bacterial adhesion and decreases the wear resistance of the restoration, irritating the adjacent soft tissues such as tongue, lips and cheeks [3-6].

Surface rugosity is a factor of bacterial biofilm formation favourable to the development of periodontal disease, due to bacterial proliferation on the surface [1, 4]. In addition, the discomfort of a surface of 0.3 µm or more is felt as rough by the patient [7]. Thus, polishing will act not only on the final gloss and aesthetics, but also in the removal of these rough surfaces that provide accumulation of biofilm and staining [3, 7-9]. When polymerized after using a Mylar strip, the composite resins have an apparently smooth surface, but with the finishing, a rough surface is formed, which must be removed with the polishing [9, 10]. However, for the polishing to be effective, the correct execution of the technique and the use of good materials (resins and polishing systems) are fundamental [9]. The characteristics and composition of the material may be more influential in the formation of the biofilm than the surface roughness itself [11].

The polishing protocols can be multi-step or one-step. Eventually, systems with sequential wear of abrasive particles, from the coarsest to the finest grain, perform better when compared to single-pass - which are simplified and require a gradually decreasing pressure [8, 9]. However, the polishing capacity of the material should not be judged solely on the basis of its abrasive compositions or sizes [6, 12]. The smoother surface that can be obtained in a composite resin is possible through the use of Mylar strip [10, 13-15]. However, this surface presents a lower hardness and, to avoid wear and discolouration, it is suggested the finishing and polishing [14, 16, 17]. All restorations require a final finishing and polishing, especially for contouring the restoration margins. Therefore, different products are available for use in the finishing and polishing of resinous composites, such as: diamond burs, flexible discs, rubber points and finishing strips [2].

Despite the variety of systems available, the polishing quality does not depend only on the polisher used, but also on its interaction with the material to be polished, since the size and shape of the filler and the composite resin matrix can influence the rugosity of its surface [18-20]. Thus, the clinical success of the final surface smoothness will depend on the finishing method, polishing and the type of composite resin selected [12, 21]. The aesthetic and chromatic characteristics of restorations should also be considered, as they can be influenced by lighting conditions and optical properties, for example: transmittance, light dispersion, fluorescence and opalescence, in addition to factors that may in the long run compromise the longevity of the obtained smoothness and gloss, such as: biofilm, acid erosion, water sorption, occlusal and thermal tensions, degradation and others [12, 20, 22].

In view of the clinical relevance of the final polishing stage, knowledge about the behaviour of the existing finishing and polishing systems is understood as primordial, in order to guarantee the achievement of an adequate surface smoothness to the restorative material, aiming at patient comfort, aesthetics and clinical longevity of the restoration performed. The objective of this in vitro study was to verify the performance of three different polishing systems (multiple-step and one step) over the surface rugosity of a nanoparticulated composite resin, considering that multi-step systems (decreasing granulation) are often associated with better polishing results.

Materials and Methods

The compositions and manufacturers of the polishing materials used in this study are detailed in (Table 1). The surface rugosity of 60 specimens of Filtek Z350 XT (3M ESPE, St. Paul MN, USA) nanocomposite resin for use in direct restorations was measured after finishing and polishing with three different systems (n=20): Sof-Lex Spiral (3M), DFL Polishers (Nova DFL, Taquara, RJ, Brasil) and Enhance (Dentsply, York, PA, USA):

i. G1: Z350 XT + finishing and polishing with Enhance (Dentsply);

ii. G2: Z350 XT + finishing and polishing with DFL Polishers (Nova DFL);

iii. G3: Z350 XT + finishing and polishing with Sof-Lex spiral (3M Espe).

Table 1: Polishing material, abrasive particles and manufacturer of materials.

|

Materials |

Abrasive particles |

Manufacturer |

|

Sof-Lex Spiral |

Aluminium oxide

particles: medium (29 µm), fine (14 µm) and ultrafine (5 µm) |

3M ESPE, St.

Paul, MN, USA |

|

DFL Polishers |

Stainless steel rods with

hardsiliconized rubber tips |

Nova DFL, Taquara, RJ, Brasil |

|

Enhance |

Aluminum oxide

and silicon dioxide (40 µm) |

Dentsply, York, PA, USA |

I Preparation of the Specimens

The specimens were made in a metal matrix containing 5 x 3mm (Figure 1). Each composite resin specimen was polymerized in two 1.5 mm thick increments and, on the last increment, a strip of Mylar and a laminula were pressed for further photoactivation (Radii-SDI, SDI - Sydney, Australia), with light intensity 1,200 mW/cm, for 40 seconds per increment. All were stored in distilled water at 37ºC in an oven for 24 hours.

Figure 1: Composite resin specimen preparation.

Figure 2: Rugosity analysis with the Surftest SV 400 rugosimeter.

II Surface Rugosity

Afterward, the specimens were submitted for analysis on an individual rugosimeter, to verify the baseline rugosity, with the equipment "Surftest SV 4f00" model CV-2000 Contracer (Mitutoyo, Tokyo, Japan) (Figure 2). Then, after finishing and polishing procedures according to the manufacturer's instructions - with a time of 30 seconds for each specimen - the specimens were washed with air-jet and distilled water, dried and then analysed on the rugosimeter again to determine the final surface rugosity.

III Statistical Analysis

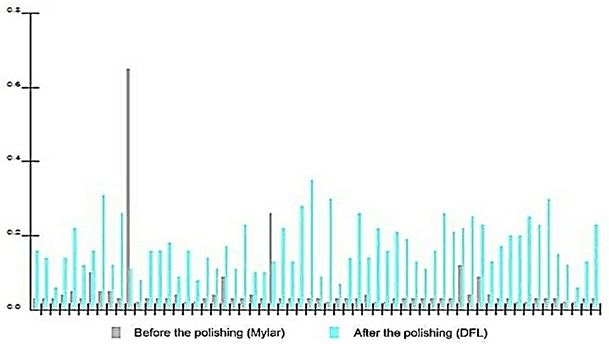

The Shapiro Wilk test was used to evaluate the normality of all data (p> 0.05). Subsequently, the results were analysed by two-factor analysis of variance (ANOVA, two-way), and Tukey's post hoc test was used to identify the statistical difference between the groups, with 95% confidence interval (p<0.05). The results corresponding to the averages, before and after polishing, are represented through the following charts (Charts 1-4), where the average values corresponding to the initial rugosity analysis, referring to the control group, made with mylar strips, were lower than the polished samples.

Chart 1: Mean surface rugosity, before (baseline) and after polishing (final).

Chart 2: Rugosity values (µm), before and after polishing with Enhance (G1).

Chart 3: Rugosity values (µm), before and after polishing with DFL (G2).

Chart 4: Rugosity values (µm), before and after polishing with Sof-Lex (G3).

The Sof-Lex (G3) polishing system showed the lowest mean surface rugosity. In the evaluation of the interactions between the effects (composite resin and polishing system), by means of the 2-factor ANOVA, there were statistically significant differences (p=0.04) between the Sof-Lex system and the DFL system. When comparing the groups polished by the DFL and Enhance system, there were no significant differences (p=0.14); likewise there were no significant differences between the Enhance and Sof-Lex systems (p=0.17). Thus, the results indicated that, among the polishing systems evaluated, the Sof-Lex spiral shows itself as an assertive option for the polishing of the composite resin evaluated, followed by the DFL Polishers and Enhance.

Discussion

The Mylar strip was chosen for the control group of the study, and provided lower surface rugosity values in relation to the polished samples, corroborating with other studies [10, 13-15]. This apparently polished surface appears due to an exteriorization of the organic matrix of the resin, something that, however, decreases the resistance of the material; therefore, it is necessary that the restorative procedure is finished with adequate polishing, preventing alteration in the material properties [9, 17]. The quality of the finishing and polishing depends on the interaction between the restoring material and the polishing system. Less resistant resins present a greater tendency to wear and rugosity when compared to those with more resistant charged particles. That is, the presence of large-sized filler particles or a large volume occupied by the organic matrix provides the surface rugosity [3]. In this study, a nanocomposite was used, which, therefore, presents excellent polishing retention characteristics.

The 3M Sof-Lex spiral polishing discs performed well in this and other studies, presenting the lowest mean surface rugosity [1, 7, 9]. This result can be justified for some reason, such as: the presence of sequentially smaller abrasive particles with this system (1-8 μm), providing a better polishing, or the fact that this system is the one recommended by the manufacturer [9, 12, 18-21]. On the other hand, systems that have bigger granules (>40μm) and are of a single step, as the Enhance system, can present bigger average values of rugosity, even presenting a superior shine [2, 14]. In the results presented in this study, the mean rugosity obtained was 0.3 μm, which is higher than the clinically acceptable value for a composite resin restoration, which is 0.2 µm - a fact that corroborates with the study of St Germain and Samuelson, where this value was also high when this same polisher was used in the Filtek Supreme Ultra, Grandio SO and Venus Pearl resins [2].

But, it is relevant to point out that the same polishing system may not interact in the same way in all composite resins; that is, the same system may act in an excellent way in certain composites and in others not [9]. There is no consensus in the literature about which instrument is the most suitable for each type of composite resin, but some studies indicate that ideal is to use the system recommended by the manufacturer himself, which has already been tested to provide better results in the material cited [18-20].

Within the limitations of the study, it was found that, in fact, multi-step polishing systems (sequentially smaller granulations) perform better in the surface smoothness of the material. Since this is a laboratory study, the results in a clinical reality may present themselves in various ways, taking into account factors such as the skill and technique of execution of the operator. Moreover, in the present study just only one composite resin was used, which presented good results with the polisher indicated by its manufacturer; therefore, it is suggested that studies with this same system be conducted, but in different composites.

Conclusion

The lowest surface rugosity of the composite resin evaluated in this study (Z350 XT- 3M) was obtained after polishing with the multi-step system (Sof-Lex), from the same manufacturer. Considering the limitations of the in vitro study, it is suggested that clinical studies be can prepared for further comparison.

Article Info

Article Type

Research ArticlePublication history

Received: Fri 16, Jul 2021Accepted: Fri 30, Jul 2021

Published: Wed 18, Aug 2021

Copyright

© 2023 Lara Pepita de Souza Oliveira. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Hosting by Science Repository.DOI: 10.31487/j.DOBCR.2021.03.04

Author Info

Lara Pepita de Souza Oliveira Moises Aleli Gomes Jefter Haad Ruiz da Silva Cláudia Cândida Silva Danielson Guedes Pontes Diego Ferreira Regalado

Corresponding Author

Lara Pepita de Souza OliveiraPostgraduate Student, Oral Rehabilitation, Faculty of Dentistry, Federal University of Amazonas, Brazil

Figures & Tables

Table 1: Polishing material, abrasive particles and manufacturer of materials.

|

Materials |

Abrasive particles |

Manufacturer |

|

Sof-Lex Spiral |

Aluminium oxide

particles: medium (29 µm), fine (14 µm) and ultrafine (5 µm) |

3M ESPE, St.

Paul, MN, USA |

|

DFL Polishers |

Stainless steel rods with

hardsiliconized rubber tips |

Nova DFL, Taquara, RJ, Brasil |

|

Enhance |

Aluminum oxide

and silicon dioxide (40 µm) |

Dentsply, York, PA, USA |

References

1.

Pala K, Tekçe N, Tuncer

S, Serim ME, Demirci M (2016) Evaluation of the surface hardness, roughness,

gloss and color of composites after different finishing/polishing treatments

and thermocycling using a multitechnique approach. Dent Mater J 35:

278-289. [Crossref]

2.

St Germain H, Samuelson

BA (2015) Surface characteristics of resin composite materials after finishing

and polishing. Gen Dent 63: 26-32. [Crossref]

3.

Babina K, Polyakova M, Sokhova I,

Doroshina V, Arakelyan M et al. (2020) The Effect of Finishing and Polishing Sequences on The

Surface Roughness of Three Different Nanocomposites and Composite/Enamel and

Composite/Cementum Interfaces. Nanomaterials (Basel) 10: 1339. [Crossref]

4.

Dutra D, Pereira G,

Kantorski KZ, Valandro LF, Zanatta FB (2018) Does Finishing and Polishing of

Restorative Materials Affect Bacterial Adhesion and Biofilm Formation? A

Systematic Review. Oper Dent 43: E37-E52. [Crossref]

5.

Tosco V, Monterubbianesi R, Orilisi G,

Procaccini M, Grandini S et al. (2020) Effect of four different finishing and polishing

systems on resin composites: roughness surface and gloss retention evaluations.

Minerva Stomatol 69: 207-214. [Crossref]

6.

Chiang

YC, Lai EH, Kunzelmann KH (2016) Polishing mechanism of light-initiated dental

composite: Geometric optics approach. J Formos Med Assoc 115: 1053-1060.

[Crossref]

7.

Wheeler J, Deb S, Millar

BJ (2020) Evaluation of the effects of polishing systems on surface roughness

and morphology of dental composite resin. Br Dent J 228: 527-532. [Crossref]

8.

Lopes IAD, Monteiro

PJVC, Mendes JJB, Gonçalves JMR, Caldeira FJF (2018) The effect of different

finishing and polishing techniques on surface roughness and gloss of two

nanocomposites. Saudi Dent J 30: 197-207. [Crossref]

9.

St Pierre L, Martel C,

Crépeau H, Vargas MA (2019) Influence of Polishing Systems on Surface Roughness

of Composite Resins: Polishability of Composite Resins. Oper Dent 44:

E122-E132. [Crossref]

10. Daud A, Gray G, Lynch CD, Wilson

NHF, Blum IR (2018) A randomised controlled study on the use of finishing and

polishing systems on different resin composites using 3D contact optical

profilometry and scanning electron microscopy. J Dent 71: 25-30. [Crossref]

11. Cazzaniga G,

Ottobelli M, Ionescu AC, Paolone G, Gherlone E et al. (2017) In vitro biofilm formation on

resin-based composites after different finishing and polishing procedures. J

Dent 67: 43-52. [Crossref]

12. Ishii R, Takamizawa T, Tsujimoto A,

Suzuki S, Imai A et al. (2020) Effects of Finishing and Polishing Methods on

the Surface Roughness and Surface Free Energy of Bulk-fill Resin Composites. Oper

Dent 45: E91-E104. [Crossref]

13. Asmussen E (1983) Factors affecting the color stability of restorative

resins. Acta Odontol Scand 41: 11-18. [Crossref]

14. Ereifej NS, Oweis YG, Eliades G (2013) The effect of polishing technique on

3-D surface roughness and gloss of dental restorative resin composites. Oper

Dent 38: E1-E12. [Crossref]

15. Scheibe KGBA, Almeida KGB, Madeiros IS, Costa JF, Alves CMC (2009) Effect

of different polishing systems on the surface roughness of microhybrid

composites. J Appl Oral Sci 17: 21-26. [Crossref]

16. Daud A, Adams AJ, Shawkat A, Gray

4G, Wilson NHF et al. (2020) Effects of toothbrushing on surface

characteristics of microhybrid and nanofilled resin composites following

different finishing and polishing procedures. J Dent 99: 103376. [Crossref]

17. Hosoya Y, Shiraishi T, Odatsu T, Ogata T, Miyazaki M et al. (2010) Effects

of specular component and polishing on color of resin composites. J Oral Sci

52: 599-607. [Crossref]

18. Rodrigues Junior SA, Chemin P, Piaia

PP, Ferracane JL (2015) Surface Roughness and Gloss of Actual Composites as

Polished With Different Polishing Systems. Oper Dent 40: 418-429. [Crossref]

19. Kocaagaoglu H,

Aslan T, Gürbulak A, Albayrak H, Taşdemir Z et al. (2017) Efficacy of polishing kits on

the surface roughness and color stability of different composite resins. Niger

J Clin Pract 20: 557-565. [Crossref]

20. Carneiro P,

Ramos TM, de Azevedo CS, de Lima E, de Souza S et al. (2016) Influence of Finishing and

Polishing Techniques and Abrasion on Transmittance and Roughness of Composite

Resins. Oper Dent 41: 634-641. [Crossref]

21. Moda MD, Godas AGL, Fernandes JC, Suzuki TYU, Guedes APA et al. (2018) Comparison of different polishing methods on the surface roughness of microhybrid, microfill, and nanofill composite resins. J Investig Clin Dent 9. [Crossref]

22. Yokokawa M, Rikuta A, Tsujimoto A, Tsuchiya K, Shibasaki S et al. (2015) Influence of methyl mercaptan on the repair bond strength of composites fabricated using self-etch adhesives. Eur J Oral Sci 123: 46-52. [Crossref]